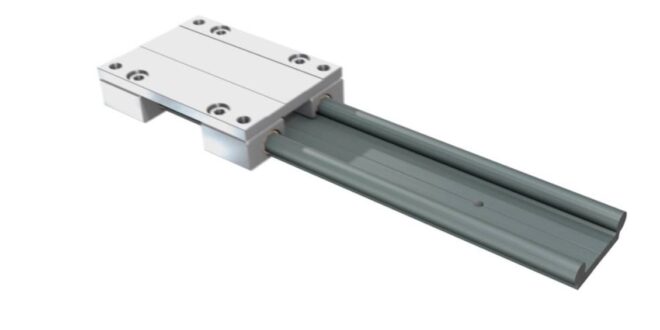

If you are looking for good travel accuracy and high stiffness, then you are on the lookout for linear guide rails. These are really multidimensional as they not only support downward and upward but are also highly adept in facing side loads and are capable of withstanding overhung. Moment loads are also in the mix, which truly adds to their usage. But, it would be best if you did not forget that in the end, the capacity is going to lie on the back of the size of linear rail and bearing system. Furthermore, it also comes down to the position of the rails. The amount of overhang and the load it can carry will also depend on the role of the bearing raceways. In this department, you have two choices – back to back and face to face.

If you opt for face to face arrangement, which is also known as the X one, the capacity spreads equally in all directions. But beware, this doesn’t make things ideal, as the moment arm is going to be shorter. This is important because the overhung loads are applied to the moment component. All of these things combined are sure to make the capacity levels lower. The other option you have at your disposal is the O arrangement, which is the back to back one. If this is your choice, you can count on a larger moment arm. Besides, you will also receive load capacities at a higher moment.

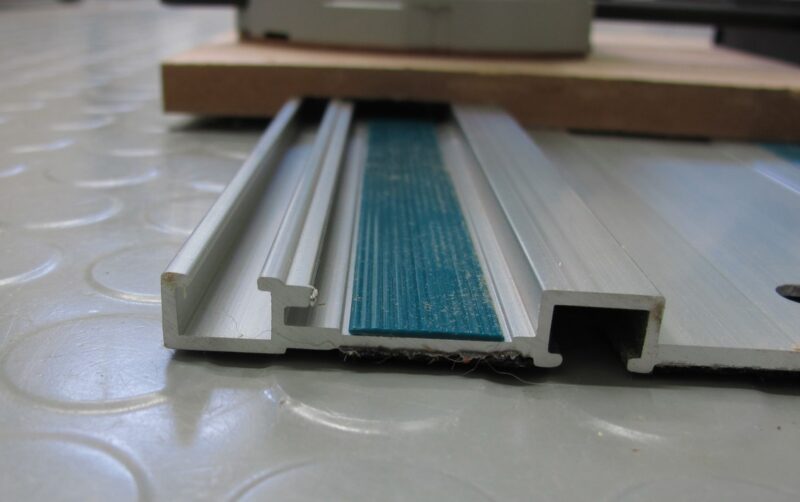

While the back to back option sounds impressive, it is not going to make things ideal. The O arrangement also has a short distance between raceways regardless of it being part of linear guides. The widest they can go is to the width of the rail. This option comes with a massive downfall in the shape of reduced ability to deal with roll moments. These roll moments are caused when loads get to overhung, which are going to the Y direction. When this happens, you need to know how to react. In fact, it would be better to prevent this movement. This is done by going against this limitation by applying two parallel rails, both of which are having two bearings on them. Thanks to this, you’ll be able to resolve the roll moment on both sides of the bearing block.

In this department, you should know that linear bearings are proud of their capacity to handle forces much better than they can take moments. The biggest issue they can face is, in fact, the roll moments. These things combined are what give the bearing life and increased lifespan. You should also know that this is not where the story ends for the benefits of this system. Dual guide rails have much more to offer. They’re also capable of resolving moments into forces. This happens because linear bearings, when faced by pure power, deflect less, while they tend to suffer when pressed against moment loads.

When the drive mechanism, in the form of a belt, screw, or linear motor, is incorporated between the rails and has two rails in parallel, you can tell it was done by a linear actuator. This is quite a typical design among them. While things are done like this often, it is not always necessary to have the drive settled in the center between the guide rails. But, once they are, it’s because it has common sense. When things are done like this, the load is dispersed on all bearings equally, which typically reduces the clogging.

Furthermore, it helps in equal share of the force on all bearings, without one end having to accept more of it, damaging the mechanism. If you want to see one while operating, be sure to try out the linear guides from tuli-shop.com. Once set, you’ll notice that thanks to the arrangement we explained, the actuator’s height will be reduced. This will make it somewhat compact, but it will not lower its ability to accept load or decline the moment capacity coming from the dual guide rails.

Dual Guide Rail Applications

As you can see from the lines above, dual rails are used when high load moments are in-game. This is precisely why they’re deployed in pairs. When set like this, they can put the force on the bearing blocks with an equal amount. The drive mechanism is, as we already said, mounted in the middle in most scenarios. It’s what makes this system compact. Now, let’s take a look at what are the applications of this system.

* Linear Stages – the stages in question are system which is based on precision. What these signals are the accuracy on high travels, and almost no deflection included. This is a must, even if the load is centered with precision, or there isn’t even moment loading. It is because of the linear stages that the stiffness and the bearing are out to the maximum.

* Machine tools – just like the linear stages, with machine tools, it all comes down to precision. They need to have high travel accuracy and stiffness. This is the only way to ensure that the machine in question is going to produce an ideal part. The deflection is minimized by using two parallel rails, which both have two bearing blocks. These machines are made to operate with high loads, which is essential to ensure the bearing life.

* Cartesian robots – if you know what Cartesian robots are, then you know that they only allow on the linear system per axis. This is standard in the industry. It is set to ensure that the axis can bear the moment’s load when under pressure. It’s not hard to understand, after reading this, why are the Cartesian robots made with linear actuators that have two parallel linear guides.

Conclusion

While guide rails might not sound like something you’ll use every day, after reading this article, you know better. They have a vast appliance in different industries but can also find their way to any home on the planet. This is why it’s vital to learn at least the basics about them in this article.

Comeau Computing Tech Magazine 2024

Comeau Computing Tech Magazine 2024