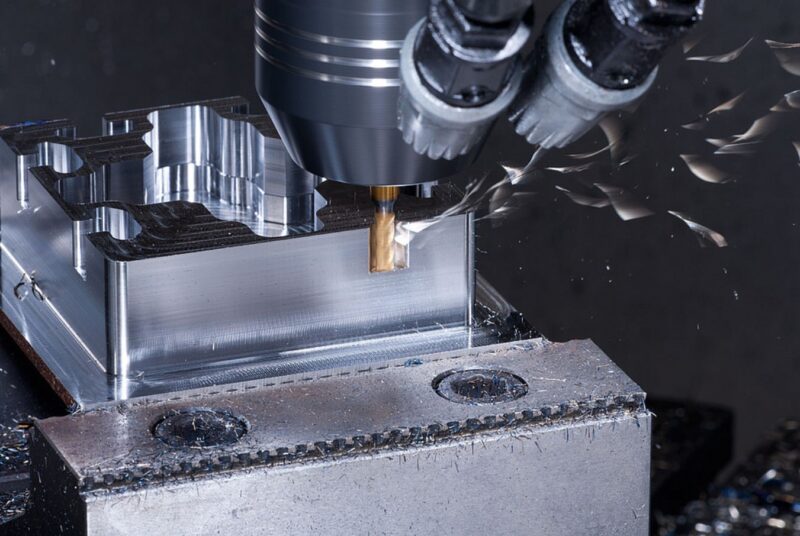

CNC machining is an industrial technique that utilizes pre-programmed computer software to control machining tools. It is a technology that manufacturing firms employ in executing various complex processes such as milling, turning, drilling, punching, lathing, grinding, and routing.

Today, the machine industry cannot be imagined without the usage of the most modern equipment, that includes these machines. In comparison to the machines that were formerly used by industry and which had to be manually controlled, these machines are operated by computers. They are additionally equipped with the control units and a servo motor on all axles.

CNC machining technology is a leading process of machining today, and companies such as bjorntoft.dk which provides CNC machine services exist today to simplify and enhance production and manufacturing tasks in industries. Employing CNC machining technology is beneficial to a company, and its benefits can be witnessed from the moment this technology is implemented.

The following are some of the major and obvious benefits of employing the services of a CNC machining service company. However, you can be assured that CNC machining technology has far greater benefits both within and outside the company utilizing it.

Benefits of CNC Machining

1. Improved machining accuracy

With CNC machining, you only need to program a product’s specifications to the computer once. What happens next eliminates any worries that you may be having in regards to varying product quality. the CNC machine perfectly replicates the design of the products as entered in the computer. Thus, CNC machining ensures consistency and precision in production.

This kind of machinery is able to produce parts with a precision level so high, that was almost unreachable by the tools used in the old days. In a classic factory, the workers were forced to manually handle different tools which often led to mistakes. But these machines can perform the same task without fatigue and can work non-stop. This contributes to many things, such as increased accuracy of the tasks performed, time saving, reducing the amount of waste, since there are less parts with irregularities that need to be disposed of.

It is also possible to produce a large quantity of exactly the same products at the same time or as per the occasion. The differences that can occur between products are usually negligible, and are caused by the wear of tools and machine parts.

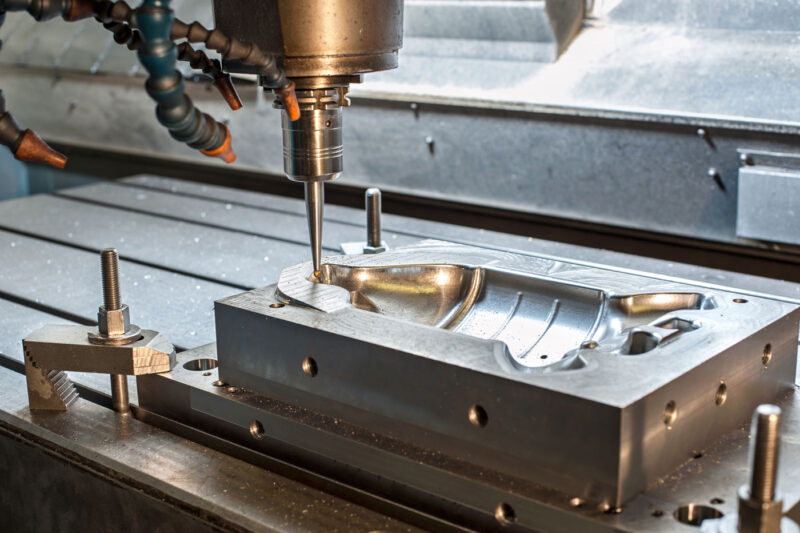

2. Enables complex tasks

There are manufacturing tasks that are beyond human capabilities. Such tasks usually risk the health and safety of employees. However, CNC technology employs computer meticulousness to operate and surpass all human limitations. That way more complex and intricate operations within an organization become possible.

Some machines are able to perform multiple tasks, and are called universal CNC machines. They are primarily used in productions of different types of products, and make it possible to switch from producing one product type to another in a very short period of time. While doing this they ensure the universal way of accepting and fixing the piece that needs processing. Besides enabling different product manufacturing, they also perform several types of processing.

Those that are only able to perform one specific type of function are called specialized CNC machines. The difference between the one we mentioned before is that they are used for a single product (specialized product).

3. Facilitates flexibility

Customer demands vary and shift from time to time. Therefore, an organization ought to be flexible enough to quickly adapt to the changing demands as this can greatly benefit the organization. CNC machining makes this possible as it uses a technology that can easily be reprogrammed quickly to produce various parts. This enables an organization to meet the shifting client demands

4. Increases safety

Industrial and manufacturing activities are mostly dangerous and put an employee in harm’s way. Such activities usually require the company to insure the employee greatly, and in case an employee suffers injuries or loses his or her life in the process, the company incurs a lot in settling the matter.

However, the use of CNC machining services makes it safe for employees to operate. The complex and dangerous tasks are performed using CNC machining technology.

5. Boosts production volume

For one, CNC machining increases business output. That is because CNC machines can work round the clock unless there is a technical hitch with the machines that have necessitated repair or maintenance. Therefore, there is a reliable production.

Also, with the design parameters and specifications fed into the CNC machine, then the machines can work consistently producing large quantities of produce. That way, the production volume of the company expands and can meet even the most unexpected demands.

By using these machines for the production of larger series of products, it is possible to plan production very precisely, resulting in much smaller losses of production time, and thus higher production productivity.

6. Reduced costs of operation

Usually, the greatest sources of manufacturing costs in a company are labor and materials. A company normally hires individuals for every activity in the organization. However, with the implementation of CNC machining technology, labor requirements are cut down by a great margin.

The company may only consider employing one skilled machine operator and a supervisor. The CNC machine then accomplishes the rest of the tasks. Moreover, operating using CNC technology ensures there is reduced material wastage.

The CNC machine uses the materials effectively, unlike if the processes were being controlled by humans. Also, there is reduced waste in regards to products not meeting the required standards or specifications. Therefore, the reduced labor costs and material wastage result in reduced costs of operation.

7. Reduced storage costs

The usage of these machines greatly influences the reduction or completely eliminates the storage costs from the list of yearly expenses. In order to keep their function, machines must be regularly maintained. After a certain time, individual parts must be replaced. These parts need to be secured by the machine manufacturer.

If the parts are made on classical machines, the manufacturer must produce and store these parts, to be able to deliver them to the customer five or more years after. Storing the spare parts creates an expense. Some of these parts are never delivered to the customer because the design of the machine changes in the meantime and the parts become obsolete.

The usage of CNC machines requires only the storing of the programs according to which the parts are made upon the customer’s order in a short period of time. The cost is significantly less than for the storage of already produced spare parts.

Conclusion

CNC machining technology greatly benefits an organization that is keen on implementing it in its manufacturing operations. The machines work to reduce costs, increase profit, and ensure accuracy, consistency, and precision in the manufacturing processes. Moreover, worker safety can be guaranteed as the complex and harmful tasks are directed to CNC machines. Thus, companies should adopt this technology and consider even employing CNC machine services.

Comeau Computing Tech Magazine 2024

Comeau Computing Tech Magazine 2024