We all know that the demand of the consumers is getting bigger by the day. We want things to be faster, stronger, more durable and to be easy to use. Do you know that in the US alone people spend more than 20 trillion dollars per year? So, for factories to be able to get all the products on the market when people need them, they need modern technology. The manufacturing industries are the ones that make everything happen. No matter if you need tools to create your own patio or if you need your business to work better with the right equipment that’s all possible because of the manufacturing industries.

The main industries that fall under manufacturing are tobacco, food and beverage, plastic, metal, electronic, transportation as well as many others. As you can see, pretty much everything you do or consume every day was made by these industries. One interesting fact is that in the US alone, there are more than 15 million people who are working in these businesses and that number is almost double if we count the people who are employed indirectly.

For these businesses to be able to make consumers happy, they need to follow the latest trends. They need to create better things that are more accessible, to provide safer workplaces and to make the whole production process faster. Here we are going to talk about the modern technologies that are implemented in manufacturing and how they are changing the whole work process.

1. Robots and automation

In the past, everything was done by the human crew. That meant that the production process was sometimes slower, human error was normal and the safety of the crew was sometimes compromised.

Nowadays, most of the production processes are automated and robots are used to help with manufacturing. Experts say that from start to finish robots are used and they are preprogrammed to finish their tasks. Some of them have cameras implemented that help them in doing the tasks correctly. However, there is still a lot of room left for improvement and in the future, we expect the automation processes to be part of every company.

This is good for everyone, starting from the industry, up to the employees and the customers. Things are getting done faster, the crew is safer and the consumers can buy better things and they are delivered faster.

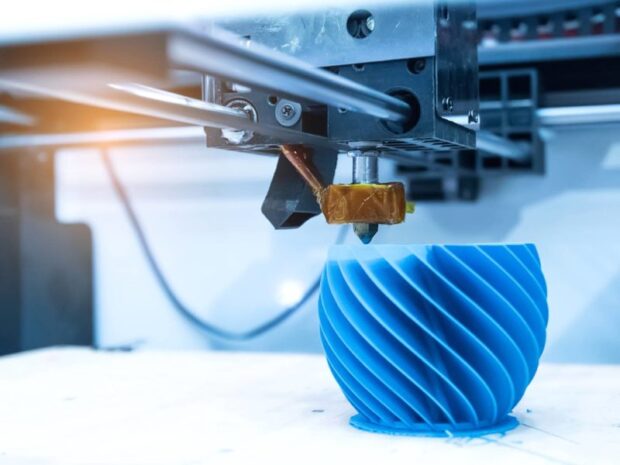

2. 3D printing

3D printing is a relatively new technology and it is still tested. However, many companies are using this to create new things and make the industries better. It is said that in the next few years, the industry will be worth more than $25 billion. This number shows in how many places 3D printing is used.

At the moment, 3D printing is mostly used for academic purposes and medicine, but many other manufacturing industries are adopting the process. In software and data management, this process is used to design and build necessary components that make technologies even better.

3. From B2B to B2B2C

In the past companies functioned in the business to business models. However, nowadays they are focusing more on business to business to customers’ models. This is happening because the current technologies are allowing companies to understand what consumers want, and with that increase sales.

Different equipment is used to make this happen, and when the consumers get what they want, they are more likely to purchase more products or to go back to the same store again. For example, CNC routers are used to engrave or emboss things in most items, and with that, the items can become personalized and they can be unique. No matter how much you think you know about modern equipment you can always read more and learn how different production processes are implemented.

In B2B2C the new tech is helping companies with faster marketing, as they can test their products faster, make them better and develop them in time for delivery. Businesses are also able to change prices depending on the customers and the manufacturer’s suggested retail price.

4. Safety equipment

We know how important safety is and, in the past, most companies were using only basic safety equipment. As time goes on and as the technology is advancing, there are different types of equipment that help keep the crew safer.

Starting from goggles up to smart devices, many modern things are used in the manufacturing process so that crew is safe. They even wear smartwatches that follow their movement, heart rate and other things that ensure safety. Now, if anything bad happens, the company is able to react faster, take all the necessary steps and to ensure that the worker is okay. In the past, this whole process was slower and the lives of the workers were at greater risk.

5. New materials

In the past few decades, scientists and manufacturers have been working on new materials, as well as new alloys that they can use in the production process. These materials are created to be more durable, to withstand extreme temperatures and to be lighter.

This means that companies can transport the machines faster, they are able to use them to reach higher places and they will stand the test of time. The new materials are used mostly in building robots and the automation process. This also helps with fuel consumption, as products made from the new materials don’t need as much power or fuel to function and that impacts the environment in a good way.

6. Cybersecurity

With new tech, the manufacturing process is mostly digitalized. Overall, this makes things a lot simpler, scientists are able to follow the data in faster means and they are able to make the needed changes. However, when everything is digitized, there is a bigger risk for security breaches and things getting stolen.

The new technology helps here as well, as there are better antivirus programs that keep all the documents safe. Physical and digital security systems are preventing most thefts and ensure the advancement of the manufacturing industries.

There have been many technological advancements and we are expecting things to change even further. It is safe to say that the sky is the limit and that we can expect even more creative things that will make our lives easier. When manufacturers combine most of the technologies together, they end up with a faster production process, better equipment, and skilled workers.

Comeau Computing Tech Magazine 2024

Comeau Computing Tech Magazine 2024