There are several components in this world that help to provide overall value in more ways than one. Many of us are not aware of these aspects and why they matter, but our quality of life would be completely different without them.

It is indeed thanks to many different discoveries in many critical parts of the industrial and manufacturing settings that we are able to experience the level of quality and progress in places such as healthcare and the industrial setting today.

While it may be useful to be oblivious to many of these small but profound components and substances that add value to our lives today, it is essential to learn about a few of them that help in several ways.

One of these essential components is parylene. It is a substance that has found favor in many manufacturers’ eyes and is present in many items that are crucial that can range from medical devices to other pieces of equipment that help to sustain life, flight, and parts of transportation.

Here is a simple but comprehensive guide to assist you on your journey to learning all about this powerful substance. By the end of this guide, you will have more knowledge of the overall properties, positives, and general uses of this simple but effective substance. See more about parylene coating here.

The Foundations of Parylene

Different companies and firms have been using parylene for over several decades. It has been in more widespread use for over thirty years in many critical settings of society.

It was a substance that was discovered before the 1950’s and has been able to take over the role of conformal coating for various uses in industries that range from aviation to national defense and even in electronics intended for everyday use.

That is why there is more research and experience with the benefits, the power, and the simplicity of parylene coating that is present in the general marketplace today.

As you may seek to use this reliable resource within your operations, you must understand more about its fundamentals and range of use cases as you assess it for further product development critical needs.

The first point you must realize is that while parylene is robust and useful in many areas and product development settings, it is not suitable for every single manufacturing need. The truth is that no technology is perfect for all types of needs as each of them have their specific properties that add value in specific areas.

But at the same time, engineers turn to this powerful technology because it possesses several characteristics that matter. These characteristics include comprehensive protection, temperature resistance, conformability to other substances, providing tranquility for manufacturers, and minimizing liability.

What is this Technology?

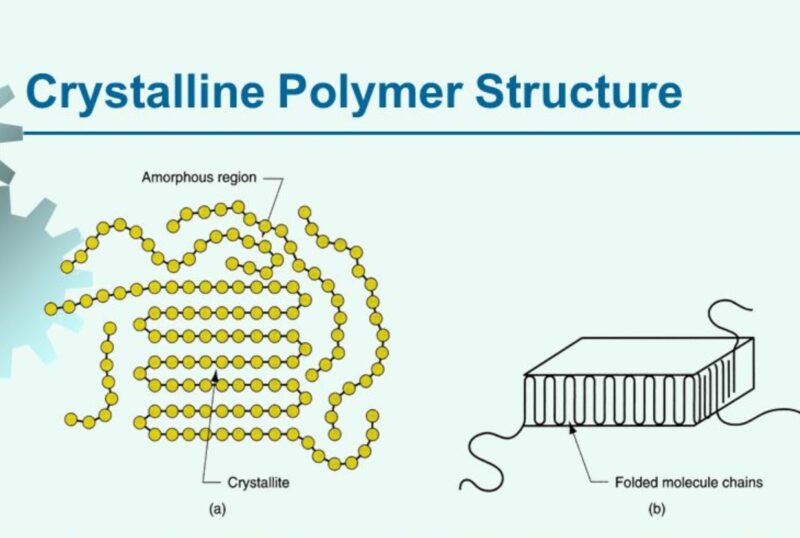

Parylene is merely a name known in the business to describe a certain category of tremendously crystalline polymers regularly found in film coating to preserve and defend sensitive equipment, devices, and small parts from turbulent and disagreeable environments.

Many people might not know that these conditions or domains may range from space travel and space equipment to the human anatomy’s deep recesses. If you will notice, even at this juncture, it shows its overall versatility.

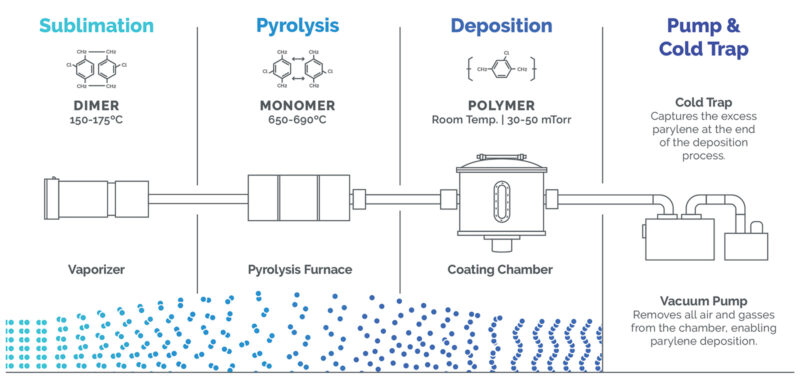

The next aspect of value when it comes to parylene coating is found in its unique performance in many types of applications because of its critical vital traits. Recall that it is a technology that has a particle-level deposition process. This process, Chemical Vapor Deposition or CVD, enables this compelling technology’s vapor to move into the smallest of physical spaces, that are hard to reach by different forms of conformal coatings present on the market.

It is able to reach these areas and blanket them with polymer particles fully, making it very useful. If you notice, it will essentially spread out similar to a substance like a mold and cover the entire area.

Manufacturers and others appreciate the deposition process because it does not have to move through a liquid part of the process. That means that you do not have to worry about using other inputs such as solvents or curing agents.

Instead, you are able to use this unique chemically robust and unadulterated substance to fully cover various shapes, surface terrains without any lapses, air protrusions, or even unpleasant and risky pinholes at a minute level.

This microscopic level of coverage enables parylene to enable comprehensive defense at a fraction of the mass of other conformal coating material. This serves as a necessary and vital value-add as modern equipment as modern consumer electronics become more dense and decrease in size.

That is why this technology is present in more parts, devices, other valuable and priceless applications within the healthcare, logistics, and national defense and aviation industries.

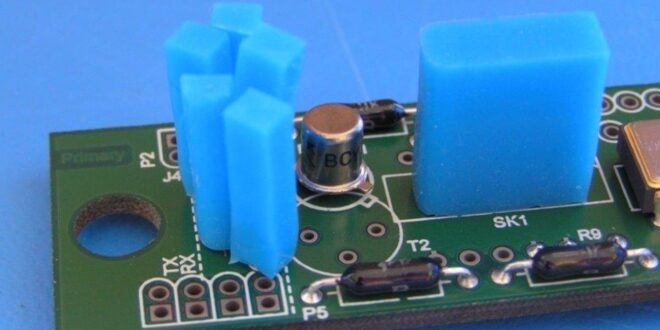

You are likely to find this coating on circuit boards, modern sensors, lights, devices that one places within the human system, medical equipment, and various items in the construction and oil and gas industry.

What is the Difference Between Liquid and Parylene Coating?

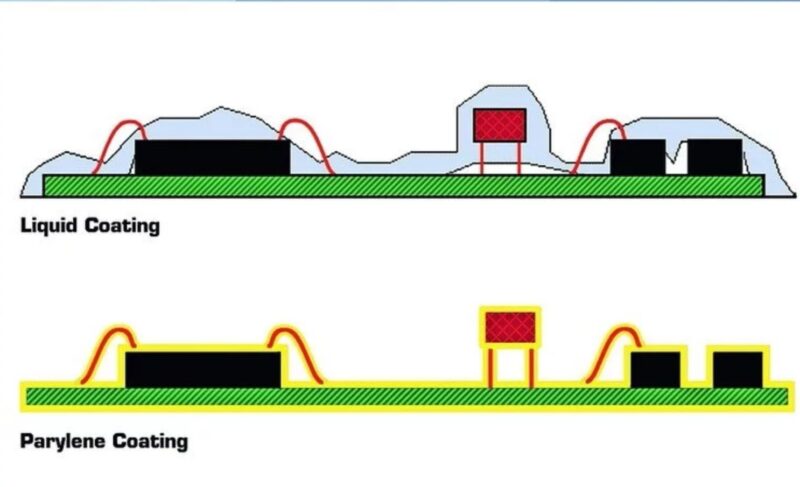

You might find that liquid conformal coating liquid is present on the market and may think about using it for your needs. But the problem with this item is that these aspects do not genuinely conform. Instead, they are known to gather and combine together in depressed places within a device while not being present at elevated and sharply protruding areas on your device or equipment.

What happens because of this situation? You will find that your devices will undergo unpleasant problems such as bubbling and even cracking, among other aspects.

The primary benefit of parylene’s behavior is its special trait of film, uniform, smooth coverage particle-by-particle that other coatings cannot reach.

It is a simple but powerful technology that continues to stand apart in many settings and provides a real value to the world overall. It is crucial in helping to save lives when placed on medical devices, to help transport people and goods when placed in aeronautical vehicles, and helpful in defense and military use cases because of its unique traits.

Comeau Computing Tech Magazine 2024

Comeau Computing Tech Magazine 2024