So, a vital part of every piece of technology is the PCB. However, they can be made of different materials. Although it is mostly made of copper foil, glass fiber or other material, there are also models made of ceramics. This is actually the most popular material in the industry. Thanks to many advantages, it is used for extremely strong electrical devices and machines. The main feature of this material is exceptional durability.

Ceramic PCB resists various conditions which is why it is a very popular material in the aerospace military industry. Of course, it is also used in others, but here you can usually find modules and gadgets with this board. The main reason is heat dissipation. However, later we will talk a bit more about the technical advantages of ceramic pcb manufacturing. Keep reading and learn all the benefits of this PCB.

1. Affordable price

This board material has proven to be a very cost effective option. The reason is that ceramics on the market really don’t cost much, but that’s not all. Ceramic PCB implies the absence of a substrate that is mainly made of aluminum nitrate or aluminum. Therefore, all manufacturers will significantly lower the price when it comes to ceramics. Thus, it provides less complex designs that increase performance at the same time.

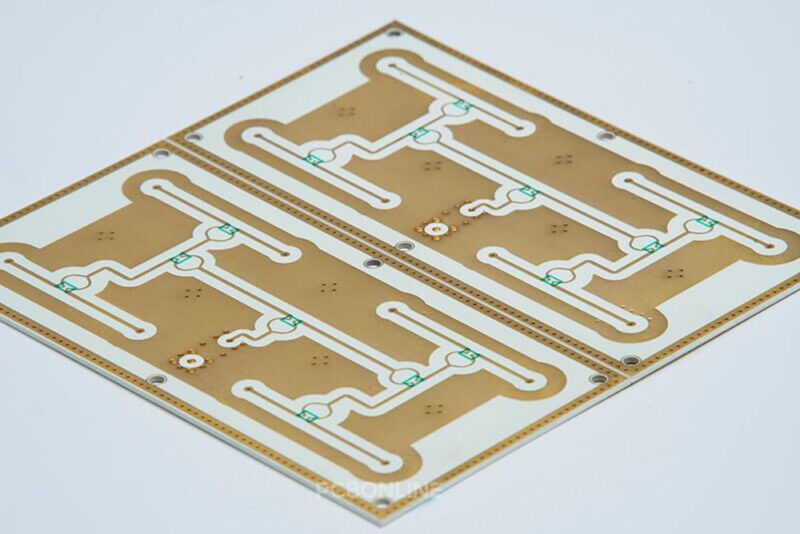

2. Multiple layers

Since these boards are considered to be a product with a very solid base, they can be made in several layers. Due to the good base, it is possible to add another layer and the components will remain in excellent condition. This is one of the main advantages, because the more complex the PCB, the more capable it will be of performing complex tasks. In this way, its performance is improved and the device will work much better. They will also be able to be applied in more complex industries that have high requirements.

3. Good insulation

The ceramic pcb has enhanced insulating properties compared to other models. Of course, the main culprit for that is ceramics, which effectively insulate electrical resistance on devices. This is especially important for all machines that often face downtime.

4. High thermal coefficient expansion

This is another reason for the great popularity of this material. In addition to providing high thermal conductivity, it can do so for a long time. In this way, the device can be maximally protected due to the transfer of thermal energy, because other materials are not up to the ceramic. In that case, not only will the device be protected, but the heat will also be regulated, and the more layers, the greater the protection against heat.

5. Resistance

Ceramic PCB, as we read at www.pcbonline.com, also has high-temperature resistance and high resistance to external influences. This applies to most chemicals used in production. That is why this board is considered a rather versatile product, because it can withstand even the most difficult production conditions. In this way, its performance remains intact until the end, while others would receive various damages. Therefore, it is considered a very flexible option, because a metal core is used in the production. This allows for mechanical stiffness.

6. Long lasting

As you know, ceramics are very durable, and durability in this whole process is very important. Thanks to its toughness, the ceramic PCB successfully resists wear and tear and ages slowly. This means that you do not have to change it often and it will take a long time.

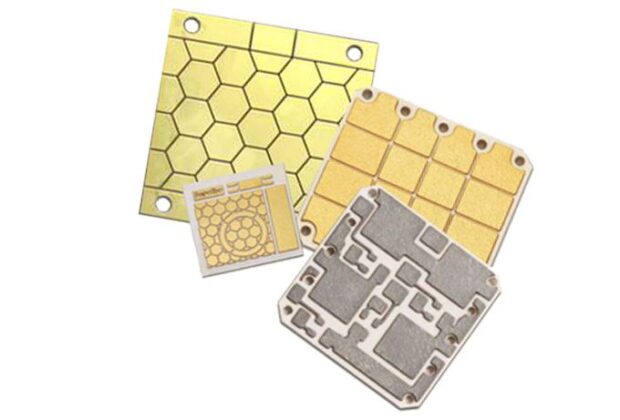

Types of ceramic PCBs

Depending on the needs of your company, these boards can be a much better choice for you compared to other materials. One of the reasons is the high thermal conductivity and low coefficient of thermal expansion, but also all the other advantages that we mentioned earlier. There are two main types of ceramic PCBs. This refers to alumina and aluminum nitride or AIN. When it comes to AIN, its main characteristics are good dielectric properties, non-reactiveness, etc. Alumina is a slightly cheaper option than the previous one, which is a great alternative for those who want to make a cheaper purchase.

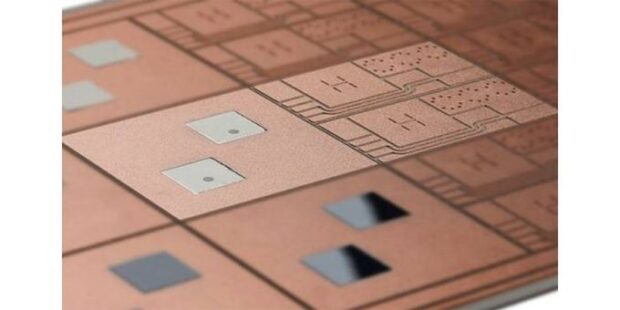

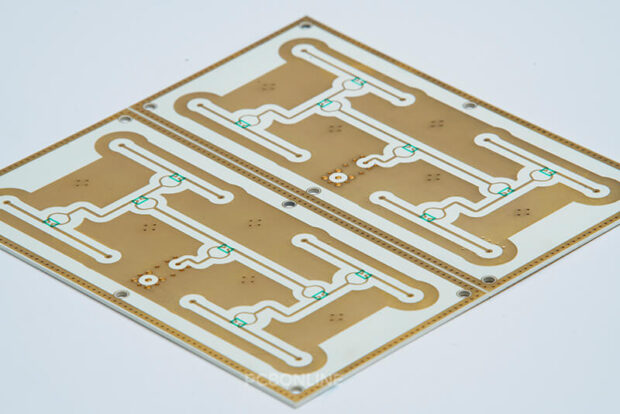

Production process of ceramic PCBs

The whole process begins with the addition of metal elements that provide conductivity. They are laid on a layer-by-layer basis. This is followed by a redbake process at low temperatures using gold or silver paste in ceramic PCBs. This allows to increase the density of components and bonds on the inner layers, because the pastes are conductive. However, this process cannot be reported with other materials and this is another reason why manufacturers are more interested in ceramic PCBs.

Different applications

What is important to note is that ceramic printed circuit boards are used in many more different places than some other types of PCBs. So we want to mention some of them. One of the main applications is for transmission and memory modules. When we talk about memory modules, ceramic PCBs can be used as part of DDR and all other electronic components that serve as memory. As for transmission, ceramic PCBs are used as part of the radar. Many years ago when it began to be used for radars in the USA, it was not a widespread technology, but today it is.

Another very important application is as part of solar panels. We all know how important it is to use renewable energy sources, and solar energy is a great example. Multi-layer ceramic PCBs are a great choice because they are durable and help with thermal transmission. Certainly coolers should be mentioned, especially coolers that are installed in small devices. Wireless power transmission is a matter of the future, but increasingly also of the present. Ceramic PCBs are an indispensable part of that.

Conclusion:

So, ceramic pcb has a lot of advantages which is why it is the most popular choice today. However, you will only benefit from good performance if you make sure that the builder has superior processing. Only then will you really get a high quality ceramic PCB.

Comeau Computing Tech Magazine 2024

Comeau Computing Tech Magazine 2024