Plastic is a material that doesn’t get much love these days, but it’s still widely used in a lot of industries. The thing about it is that it’s not eco-friendly at all, and given our current situation with pollution and all of that, people are not very fond of purchasing products made out of this particular material.

However, we cannot neglect the importance of plastic, and although there’s an alternative for things such as grocery bags and straws, we cannot say the same for items such as phone cases. The truth is, this material has to be used, but we should only limit ourselves to use it for items that are not being thrown away, such as bags and straws.

At the end of the day, it all comes down to how responsible people are with recycling because that’s the only thing that can stop the pollution. Now that we have all of this out of the way, we can start talking about our main subject, which is the different types of plastic molding.

Not many of you might be familiar with this term, but it has a lot of significance, and it’s the process through which a lot of your household items are made. You’re probably using something right now that has been created this way. Let’s take a look.

What is plastic molding?

Simply put, this is the process of using shaping items and tools, or just molds, and using them to shape plastic into a certain item, or a piece that’s required for the completion of an item. This can be anything, such as the phone cases we mentioned above, keychains, toys for children, and a lot of other different things.

There isn’t just one way of doing this however, so we’re going to focus on explaining each one of the popularly used types one by one. For detailed information about plastic molding solutions, I advise you to do more research online or visit the hyperlinked website. Let’s get into it.

Molding by compression

Although the name might sound a bit complicated, in reality, this type is probably one of the easiest to do. You still have to be careful with it, however, because it includes large amounts of heat. This is done by taking the piece of plastic and heating it to a degree where it’s very easily re-shapeable. After doing that, you can take two pieces of mold, one of which needs to be heated as well. Place the heated piece inside of the heated mold and then close it, compressing it into the shape in which you want it to be.

Extrusion Molding

If you’ve ever wondered how most tubes, pipes, and straws are made, well, extrusion molding is responsible for it. This method is widely used, but most of the things being made with it are hollow and long, which is why we gave you the three examples of items above. Instead of the injection molding machine, an extrusion machine is used for this method.

The heated piece is placed into the machine where it gets shaped, and after it cools off you can safely take it out of there.

If you are currently interested in getting your custom-made item, but you’re not sure which company to choose for the task, feel free to visit Moldall and get to know some more about many plastic manufacturers.

Injection Molding

Probably one of the most famous ways of shaping plastic into a certain form. This method uses injecting the heated material into a mold, filling it up, and then letting it cool there until it’s ready for use. It sounds very simple, and it is, but there are still some details that you have to pay attention to if you are engaging in something like this.

As you’ve probably guessed already, the presses, injections, and molds used for this process vary in size and shape, based on what the final result should be. Out of all other methods that people know of, this one is considered to be one of the most reliable and convenient ones. If you’re ever looking to get a custom-made item done, it’s most likely going to be created this way.

When it comes to usefulness, the injection method seems to always win first place. This is because it is often used to create very small and complicated parts, which are often used for a much greater cause. For example, the small and detailed parts created by the injection method are used for medical devices and equipment.

This method is best used for cases where you need to make thousands of small but detailed items, and it seems to be cost-efficient in that manner. The molds might cost a lot of money, but you’re getting a huge return on investment because of the large volumes of items that you’re producing with this method.

Rotational Molding

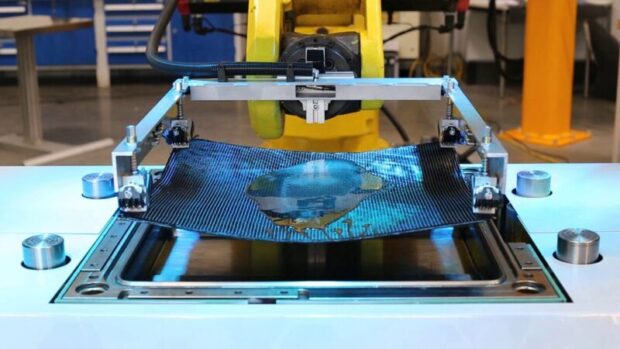

Last but not least, we have the method which uses both rotations and high temperatures combined to get the perfect shape as a final result. You might see this method being called “Rotomolding” as well, but we believe that both are correct terms.

For roto-molding, it’s pretty safe to say that it’s a more complicated process compared to all the other ones on the list, but it’s still relatively easy to understand. Here’s how it works.

After preparing a mold, you need to fill it with something called a polymer powder. When this step is done, the mold is placed on a machine where it starts to rotate in two axes. While it’s rotating, the plastic fills the right places of it, and this keeps on repeating until everything cools-off properly, and that’s when the process is stopped.

Rotomolding is mostly used for the creation of larger hollow items, such as tanks, tubes, containers, and a lot more. It’s not used for multiple-piece items. One of the biggest advantages of this process is that most of the material that’s not used for the item that’s currently being produced, can be reused later.

This is why rotomolding is often considered to be one of the most eco-friendly and environmentally-safe methods when it comes to plastic molding.

Comeau Computing Tech Magazine 2024

Comeau Computing Tech Magazine 2024